Oil bronze bushings are cylindrical bearings that offer low friction, noiseless operation, and exceptional wear resistance. They are composed of a bronze alloy material that is infused with various other metals such as zinc, tin, and nickel to enhance their strength and durability. Additionally, they have oil grooves that facilitate efficient lubrication, resulting in optimal performance and longer lifespan.

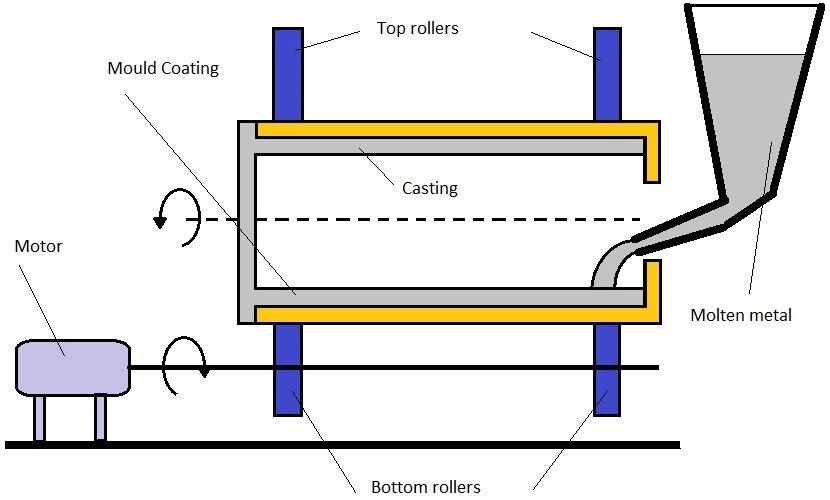

One of the most popular bronze alloys used for manufacturing oil bronze bushings is C86300. It's a high-strength and corrosion-resistant material that can withstand extreme loads and harsh operating conditions. The manufacturing process of C86300 bronze bushings involves centrifugal casting, which enables the material to achieve high dimensional accuracy, uniform density, and excellent directional strength.

High-tolerance CNC machining is another crucial step in the manufacturing of oil bronze bushings. It involves using computer-controlled machines and tools to achieve precise and accurate dimensions, finishes, and tolerances. This process ensures that each bushing performs optimally and fits seamlessly into the machinery.

Oil bronze bushings are used in various applications such as valves, pumps, conveyors, and presses. They are also ideal for use in heavy-duty equipment such as locomotives, cranes, and bulldozers. The quality of the bushings directly impacts the performance and longevity of the machinery, making it essential to source them from reputable suppliers.

In conclusion, the demand for oil bronze bushing suppliers is increasing due to the rise in demand for high-quality machinery and equipment parts across different industries. C86300 bronze alloy is among the most popular materials used in manufacturing oil bronze bushings due to its strength, corrosion resistance, and superior wear resistance. The manufacturing process involves centrifugal casting and CNC machining to achieve high dimensional accuracy and uniform density. For optimal performance and longer lifespan, it's crucial to source oil bronze bushings from reputable suppliers who employ high-quality materials and advanced manufacturing processes.